Modern Defect Detection

The Importance of Defect Detection in Modern Manufacturing

By: Destiny Dickerson

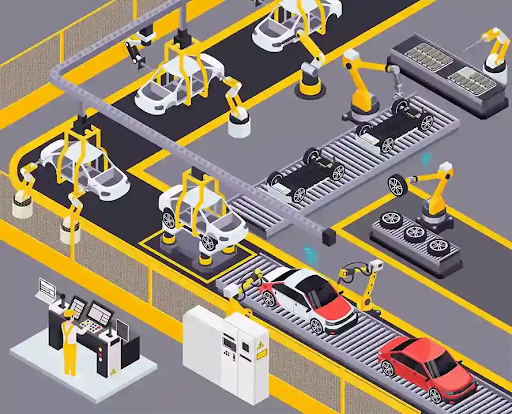

In today’s fast-paced manufacturing environment, delivering high-quality products isn’t just a goal—it’s a necessity. Whether it’s consumer electronics or automotive components, even the slightest flaw can have serious consequences. At the core of quality assurance lies defect detection, a process that has dramatically evolved with the help of modern technology.

Why Defect Detection Matters

Picture the excitement of opening a brand-new smartphone, only to realize it won’t power on. Or imagine driving a newly purchased car, only to discover the brakes are faulty. These scenarios underscore how impactful product defects can be, causing frustration and inconvenience and posing real safety risks.

Defects lead to wasted time and a loss of trust for consumers. However, for manufacturers, the implications can be even more severe. Missed defects often mean wasted materials, costly rework, and production delays. In the long run, these issues chip away at profit margins and throw off carefully planned schedules.

Even more damaging is the potential harm to a company’s reputation. In the age of social media and instant reviews, one faulty product can quickly spark widespread backlash. Safety-related defects may result in regulatory violations, lawsuits, and large-scale recalls.

By detecting issues early—ideally before products leave the production line—companies can save time, minimize costs, and protect their reputation and their customers. It’s not just about quality anymore; it’s about operational excellence.

Common Manufacturing Defects

Manufacturers deal with various defects depending on the product, but many share familiar traits. Surface imperfections such as scratches, dents, or cracks are common, as are dimensional inaccuracies where parts fall outside required tolerances. Components may be missing, installed incorrectly, or misaligned. Problems in welding or soldering can weaken structural integrity, while mismatched colors or flawed materials may impact appearance and function. Even minor issues can compromise usability or performance, especially when they go unnoticed in high-volume production.

Evolving from Traditional to Smart Detection

Traditionally, defect detection relied heavily on human inspection. Trained workers visually examined products, often using checklists to guide their evaluations. While this approach has value, it’s time-consuming, labor-intensive, and susceptible to human error, especially during long shifts or with complex products.

In contrast, innovative defect detection systems use advanced technologies to deliver faster, more accurate, and more reliable results. Machine vision systems employ high-resolution cameras and specialized software to inspect products in real-time. These systems operate continuously and maintain consistent performance with minimal human oversight.

Artificial intelligence and machine learning have added a new layer of intelligence. These tools analyze large production data volumes to recognize subtle or complex defect patterns. Over time, they become more innovative and precise, allowing manufacturers to avoid problems before they escalate.

Other technologies, such as ultrasonic and X-ray imaging, detect hidden internal flaws, particularly in mission-critical products like aerospace components or medical devices. Meanwhile, 3D laser scanning ensures every part matches exact design specifications—essential in industries that demand absolute precision.

The Benefits of Smart Defect Detection

Adopting innovative defect detection systems is more than just a technological upgrade—it’s a transformation of the entire manufacturing process. These systems can identify imperfections far too minor or complex for the human eye. Real-time monitoring allows immediate feedback and corrections, which reduces delays and lowers the cost of errors.

They also provide predictive insights by analyzing trends in production data. This enables proactive maintenance and informed design improvements, preventing recurring defects. One of the most significant benefits is increased labor efficiency. Automated systems can work around the clock with minimal supervision, allowing human workers to focus on higher-level tasks that require creativity and judgment.

In short, innovative detection technologies enhance product quality, reduce waste, and streamline operations while paving the way for continuous improvement.

Challenges in Implementation

Despite its many advantages, implementing intelligent defect detection systems has some initial challenges. The upfront investment can be substantial, as advanced equipment and analytics platforms often carry a high price tag. Integrating these systems into older, existing production lines may also require additional infrastructure upgrades and custom configurations.

Another hurdle is the human factor. Employees need proper training to use and maintain these tools effectively. Shifting to a tech-focused approach requires new skills and a change in workplace culture.

That said, the long-term gains often justify the initial costs. As the technology becomes more accessible and affordable, the return on investment grows, especially when measured in efficiency, product quality, and reduced waste.

The Future: Industry 4.0 and Beyond

Defect detection is now a core element of Industry 4.0—the era of intelligent, connected manufacturing. In this new landscape, IoT-enabled sensors provide real-time monitoring across production lines. Cloud-based analytics deliver remote insights and help predict potential issues before they arise. Self-correcting machines can automatically adjust parameters the moment a defect is detected.

As these innovations become more widespread, manufacturers move from reactive quality control to proactive quality assurance. The result is a more innovative, agile production environment prioritizing precision and reliability at every stage.

Conclusion

Defect detection has evolved from a basic quality checkpoint to a central strategy in modern manufacturing. By embracing technologies like AI, automation, and data analytics, manufacturers are not only ensuring better products but also redefining what quality means. In a future where efficiency and precision are everything, companies that can identify problems before they happen will lead the way. Intelligent defect detection is no longer optional—it’s essential.

Sources

- IBM. How AI is Transforming Manufacturing. Retrieved from: https://www.ibm.com/blogs/internet-of-things/ai-manufacturing/

- Siemens. Vision Systems for Industrial Automation. Retrieved from: https://new.siemens.com/global/en/products/automation/topic-areas/industrial-ai.html

- McKinsey & Company. AI in Manufacturing: Case Studies. Retrieved from: https://www.mckinsey.com/business-functions/operations/our-insights

- National Institute of Standards and Technology (NIST). Smart Manufacturing and Quality Assurance. Retrieved from: https://www.nist.gov/programs-projects/smart-manufacturing

- Deloitte. Industry 4.0 and the Smart Factory. Retrieved from: https://www2.deloitte.com/insights/us/en/focus/industry-4-0/smart-factory.html

- Photo by Trident Information Systems. “Defect Detection in Manufacturing: How Computer Vision Is Revolutionizing Quality Control.” Trident Info, https://tridentinfo.com/defect-detection-in-manufacturing-how-computer-vision-is-revolutionizing-quality-control/.