Backbone of Manufacturing

Mastering Inventory in Modern Manufacturing

By: Destiny Dickerson

In today’s globalized and fast-paced industrial landscape, managing inventory is more than a support function—it’s a critical driver of efficiency, cost control, and customer satisfaction. Manufacturing Inventory Management (MIM) forms the backbone of production operations by ensuring that materials and products are available at the right time, in the correct quantity, and at the right place. With the help of digital tools and innovative strategies, manufacturers are leveraging inventory management to gain a competitive advantage.

Understanding Manufacturing Inventory Management

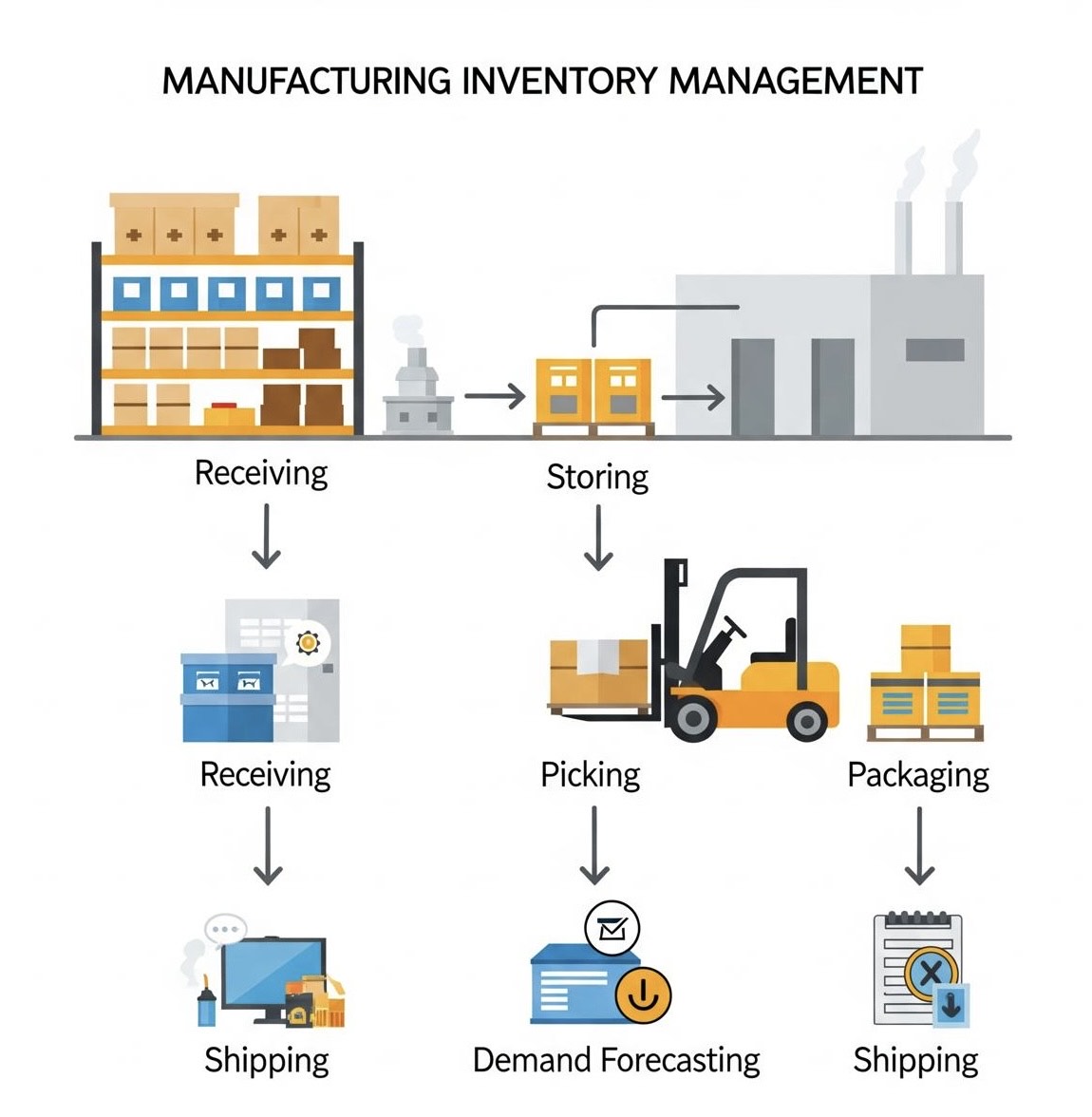

At its core, Manufacturing Inventory Management involves the supervision and control of stock as it moves through various production stages. This includes raw materials that initiate the manufacturing process, components that form part of a product, items undergoing assembly or processing—known as work-in-progress—and the final finished goods that are ready for storage or shipment. The objective is to maintain balanced inventory levels that support continuous production without resulting in excess, which can lead to higher costs and wasted resources. While traditional inventory systems once relied on manual entries and physical stock checks, today’s manufacturers require real-time, automated solutions to keep pace with rapidly changing demands and complex supply chains.

Technology’s Role in Inventory Efficiency

The role of technology in inventory management has become central to modern manufacturing. Software platforms, such as Inventory Management Systems (IMS) and Manufacturing Execution Systems (MES), provide real-time visibility and seamless tracking of materials from receipt to shipment as finished goods. Barcode scanning and Radio Frequency Identification (RFID) have replaced outdated tracking methods, significantly reducing human error and speeding up data collection. The integration of Internet of Things (IoT) devices enables sensors and machines to monitor inventory levels autonomously, even triggering automatic reorders when stock levels are low. Cloud-based inventory systems add another level of convenience by allowing departments across locations to access consistent and up-to-date information, making communication and collaboration smoother and more effective.

The Three Core Inventory Types

Inventory in a manufacturing setting is typically categorized into three main groups. Raw materials are the primary inputs required to initiate the production process. Work-in-progress refers to products that are in various stages of completion but are not yet ready for sale. Finished goods are the final outputs that are packaged and prepared for delivery to customers or retailers. Proper management of each type is crucial to prevent production delays, minimize storage issues, and avoid tying up capital in unsold inventory.

Inventory Management Strategies

Manufacturers employ various strategies to maintain control over their inventory. One widely used approach is Just-in-Time (JIT) inventory, which aims to receive materials only when they are needed for production. This reduces storage costs and material waste but requires precise timing and strong supplier relationships. Another method is Material Requirements Planning (MRP), which relies on demand forecasts, production schedules, and lead time data to predict future inventory needs. MRP systems automatically generate orders to ensure inventory levels align with production goals. Lean manufacturing is also a popular philosophy that emphasizes efficiency, continuous improvement, and the elimination of unnecessary inventory. In this approach, excess stock is viewed as a sign of inefficiency and is minimized as much as possible without compromising workflow.

Overcoming Modern Inventory Challenges

Despite the advantages offered by modern technology, manufacturers continue to face several challenges in managing their inventory. Disruptions in the supply chain, such as those seen during the COVID-19 pandemic, can make it challenging to maintain optimal stock levels. Inaccurate data, disconnected systems, and undertrained staff can also lead to costly errors. Additionally, relying solely on automation without human oversight can create blind spots. For inventory systems to function effectively, businesses require routine audits, ongoing staff training, and regular evaluations of their digital tools to identify issues early and make adjustments as needed.

The Future of Inventory Management in Manufacturing

Looking ahead, artificial intelligence and machine learning are set to transform inventory management even further. These technologies can process large volumes of data to forecast demand more accurately, recognize trends, and provide strategic recommendations. Predictive analytics enables companies to make informed purchasing decisions and minimize the risk of running out of critical materials. Sustainability is also becoming a significant focus. Many manufacturers are adopting eco-conscious inventory practices by sourcing materials responsibly, reducing overproduction, and minimizing material waste. As manufacturing becomes more advanced and data-driven, inventory management will continue to play a central role in overall productivity and business growth.

Sources

- NetSuite. “What Is Inventory Management?” https://www.netsuite.com

- Katana MRP. “Manufacturing Inventory Explained.” https://katanamrp.com

- Manufacturing.net. “How Tech Is Revolutionizing Inventory Management.” https://www.manufacturing.net

- Forbes. “The Role of AI in Inventory Optimization.” https://www.forbes.com

- MIT Sloan Management Review. “Inventory Planning in a Post-Pandemic World.” https://sloanreview.mit.edu